GK-L30 photocatalytic oxidation

Performance and Usage

The GK-L/GK-W series photocatalytic technology produced by our factory is determined based on the properties, treatment capacity, and treatment requirements of exhaust gas, and is an ideal choice for exhaust gas purification. Ensure the emission of exhaust pollutants and establish harmless and clean production processes.

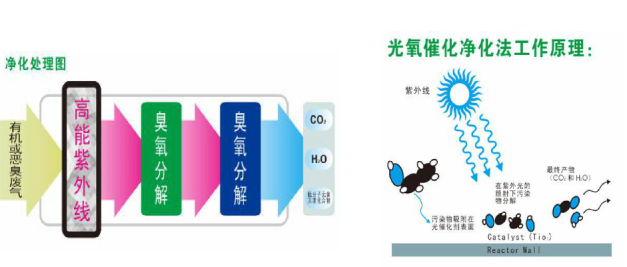

working principle

As the synthesis of compounds by humans becomes increasingly complex, the harm of high concentration and difficult to degrade organic waste to the human environment is growing. Therefore, the photocatalytic exhaust gas treatment device adopts the professional technology of purifying the molecular chain of exhaust gas using ultraviolet light source.

The first step is to use 253.7 nanometer wavelength light to cut, break, burn, and crack the molecular chains of waste gas, and change the molecular structure.

Second treatment: Take 185 nanometer wavelength light to catalyze the oxidation of waste gas molecules, so that the damaged molecules or atoms can combine with O3, and the organic or inorganic polymer odor compound molecular chains can be converted into low molecular weight compounds such as CO2 and H2O during the catalytic oxidation process.

Third level treatment: Seven or more corresponding inert catalysts are configured according to different exhaust gas components. The catalyst uses honeycomb shaped metal mesh as a carrier, which is in full contact with the light source in all directions. The inert catalyst undergoes catalytic reaction below 338 nanometer light source, amplifying the light source effect by 10-30 times, allowing it to fully react with the exhaust gas, shortening the contact time between the exhaust gas and the light source, thereby improving the exhaust gas purification efficiency. The catalyst also has a purification effect similar to plant photosynthesis on exhaust gas.

After triple treatment, the exhaust gas can achieve a deodorization rate of over 99%, and the purification and deodorization effect is significantly lower than the national odor pollutant emission standard (GB6514-2008) issued in 2008.

Nine major advantages

1. Efficient Odor Removal: It can efficiently remove major pollutants such as volatile organic compounds (VOCs), hydrogen sulfide, ammonia, flowing alcohols, and benzene derivatives, as well as various odors. The purification and deodorization efficiency can reach up to 99% or more, and the purification and deodorization effect greatly exceeds the national odor pollutant emission standard (GB14554-93) issued in 1993

2. No need to add any substances: just set up corresponding exhaust pipes and exhaust power to decompose and purify industrial waste gas through this equipment, without adding any substances to participate in chemical reactions.

3. Strong adaptability: It can adapt to high concentration, atmospheric volume, and purification treatment of different industrial waste gases. It can work continuously 24 hours a day and operate stably and reliably.

4. High cost-effectiveness: The lamp tube has a long lifespan, with a lifespan of over 12000 hours.

5. Low operating cost: This equipment has no mechanical action, no noise, no need for dedicated management and daily maintenance, only requires regular inspection and replacement of coarse efficiency filters. The energy consumption of this equipment is low, and the air resistance is extremely low<400pa, which can save a lot of exhaust power energy consumption.

6. No pre-treatment required: Industrial waste gas does not require special pre-treatment, such as heating, humidification, etc. The equipment can work normally in an environment with a temperature between -20 ℃ -60 ℃, humidity between 30% -98%, and pH between 3-11.

7. The equipment has a small footprint and light weight: suitable for special conditions such as compact layout and narrow space. The equipment occupies an area of less than 1 square meter and can handle an air volume of 10000m3/h.

8. Made of high-quality imported materials: high fire and corrosion resistance, stable performance, and long service life.

9. Environmentally friendly high-tech patented products: Adopting advanced international technology concepts and developed through long-term repeated experiments by experts and our company's engineering and technical personnel, this high-tech environmentally friendly purification product has completely independent intellectual property rights. It can completely decompose toxic and harmful substances in industrial waste gas and achieve perfect purification effect. After decomposition, the gas can be completely discharged harmlessly without producing secondary pollution, while achieving efficient disinfection and sterilization.

Model | GK-L20 | GK-L30 | GK-L40 | GK-W40 |

|

|

|

|

|

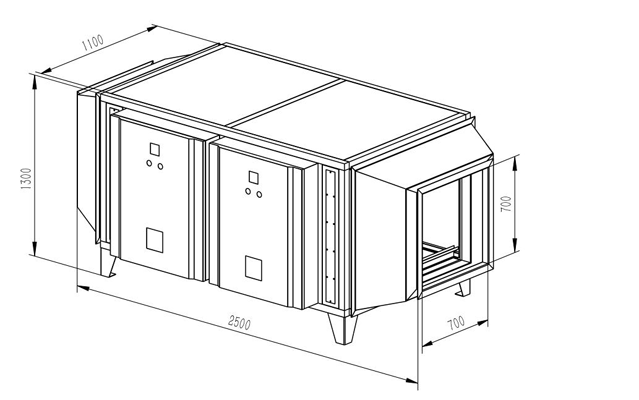

External dimensions(mm) | 1200*1040*1580 | 1200*1040*1580 | 1200*1040*1580 | 2500*1100*1300 |

Texture of material | Galvanized pipe spray coating | Galvanized pipe spray coating | Galvanized pipe spray coating | Galvanized pipe spray coating |

Photolysis lamp tube (unit) | 20 | 30 | 40 | 40 |

Processing air volume m3h | 13000-15400 | 13000-15400 | 13000-15400 | 13000-15400 |

Fan Kw/h | 5.5 | 5.5 | 5.5 | 5.5 |

Noise db | ≤75 | ≤75 | ≤75 | ≤75 |

Processing efficiency | >98 | >98 | >98 | >98 |

Contac us Add:Lanting,Shaoxing,china lndustrial Park Tel:0575-84626678 0575-84624478 0575-84624378 E-mai:mrking@shbqdy.com |

|

Copyright © 2009-2018,All rights reserved Shaoxing Dongyun Machinery Co., Ltd